Understanding Power Tools and Energy Consumption

A power tool is a tool that is actuated by an additional power supply rather than solely manual labor. When you’re using power tools, energy consumption is an important factor to consider. Each tool has its own energy usage which varies based on the power rating (the rated power), typically measured in watts (W). The amount of electricity a power tool consumes depends on its wattage and how long you use it.

For example, let’s break down the electrical terms that relate to your power tools:

- Amps (A): This is the measure of the electrical current flowing through the tool.

- Volt (V): Voltage is the pressure from the power source that pushes the current through the tool.

- Wattage (W): Watts are the product of amps and volts, representing the actual power used by the tool.

Here’s a simple way to understand this:

- Amps × Volts = Watts

To estimate the electricity consumption of your tools, you can use the following formula:

- Watts × Hours Used = Watt-hours (Wh) / 1,000 = Kilowatt-hours (kWh)

Your power tools’ energy consumption may not seem significant for short-term use, but it adds up over time.

Do Power Tools Use a Lot of Electricity?

There is no exact answer to this question. The amount of power depends on many different factors, for example, the size of the machine. In general, if you use a large machine, it can spend more electricity. If the power tool is small, the usage of electricity is not too much.

Types of Power Tools and Their Electricity Use

When you’re working on various projects, understanding how much electricity your power tools will consume is essential. If you use a tool using too much power, it can Increase your electricity bill.

Small Power Tools

Drills and Sanders: These are typically handheld tools and, being smaller, they use less electricity — around 500 to 1000 watts. Cordless drills may have even lower wattage, depending on the battery.

Larger Power Tools

Table Saws and Miter Saws: Larger power tools like these are more robust and, consequently, have higher power needs. Expect anywhere from 1000 to 3000 watts of electricity use.

Circular Saws: Falling between small hand tools and large stationary tools, a circular saw can use about 1200-2500 watts.

High Wattage Tools

Routers and Grinders: Precision tools like routers and heavy-duty tools like grinders use more electricity, typically mirroring larger power tools in wattage.

When you’re choosing power tools, always refer to the tool’s manual for specific wattage information and consider efficiency for the job at hand.

Here is a chart about the electricity usage of common power tools:

| Items | Starting Wattage (W) | Running Wattage (W) |

| Circular Saw | 2400 | 1200 |

| Drill | 1800 | 720 |

| Edger | 2400 | 960 |

| Electric Chainsaw | 2400 | 1200 |

| Electric Lawn Mower | 4320 | 1440 |

| Electric Pressure Washer | 3600 | 1200 |

| Electric String Trimmer | 1500 | 600 |

| Jig Saw | 1800 | 720 |

| Miter Saw | 2100 | 840 |

| Orbital Sander | 1800 | 600 |

| Paint Sprayer | 1080 | 360 |

| Planer | 2400 | 960 |

| Router | 1500 | 600 |

| Water Pump | 3000 | 1000 |

| Wet/Dry Vacuum | 2500 | 888 |

| Winch | 5400 | 1800 |

| Furnace Fan, gas/fuel oil furnace | ||

| 1/8 horsepower (hp) | 500 | 300 |

| 1/6 horsepower (hp) | 750 | 500 |

| 1/4 horsepower (hp) | 1000 | 600 |

| 2/5 horsepower (hp) | 1400 | 700 |

| 3/5 horsepower (hp) | 2350 | 875 |

| Central Air Conditioner | ||

| 10,000 BTU | 2200 | 1500 |

| 20,000 BTU | 3300 | 2500 |

| 24,000 BTU | 4950 | 3800 |

| 32,000 BTU | 6500 | 5000 |

| 40,000 BTU | 6700 | 6000 |

| 1/4′ Drill | 300 | 300 |

| Jigsaw | 300 | 300 |

| Electric Weed Trimmer | 500 | 500 |

| Belt Sander | 1000 | 1000 |

| Disc Sander | 1200 | 1200 |

| Chain Saw | 1200 | 1200 |

| Worm Drive Saw | 3100 | 1560 |

| 12′ Concrete Cutter | 3600 | 1800 |

| 7 1/4′ Circular Saw | 3000 | 1500 |

| Disc Grinder | 4000 | 2000 |

Factors Influencing Power Tool Electricity Use

When considering the electricity usage of your power tools, various factors come into play that can either increase or decrease their power consumption. Understanding these can help you optimize their use to be more energy-efficient.

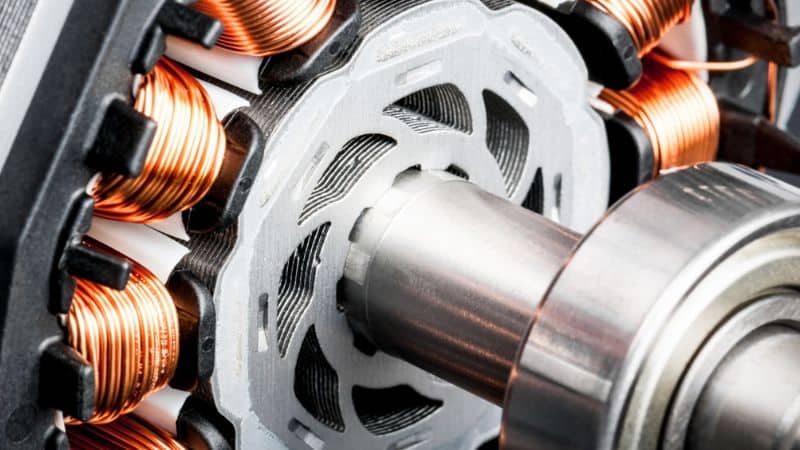

Motor Type

The motor is the heart of a power tool, with different types having different efficiency levels. Brushless motors often offer better energy efficiency compared to brushed ones.

Battery Powered vs. Corded

Battery-powered tools may be more convenient, but keep an eye on the battery’s health. Poor maintenance can lead to inefficient power usage. In contrast, corded tools might draw more power but don’t depend on battery efficiency.

Tool Load

The load your power tool handles can impact its performance and electricity use. Heavy-duty tasks will increase power consumption, so always use the right tool for the job to maintain efficiency.

Power Rating

Look for tools with an optimal balance between voltage and performance to reduce electricity consumption. Higher-wattage tools will generally use more power.

Efficiency of Power Management

Efficient power management in the tool helps in saving energy. Features like variable-speed triggers and auto-shutoff can contribute to energy saving.

Wiring and Circuit

The condition of your tool’s wiring and the circuit it operates on can affect electricity usage. Ensure that your workspace’s electrical system can handle the tools’ power needs without wasting energy.

By being mindful of these factors, you can operate your power tools in a way that conserves energy and ensures that you’re getting the job done effectively and efficiently.

Choose the Power Tool You Need

When selecting a power tool, consider the task at hand. If you’re tackling a project such as building a bookshelf, a drill and circular saw are essential. For flooring updates, a power sander is your go-to tool.

- Type of Power: Decide between cordless or corded tools. Cordless models offer portability but may have limited battery life. Corded tools provide continuous power but restrict mobility.

- Power and Torque Needs: Assess the level of power and torque based on the material and job complexity.

- Ergonomics: A tool’s size and weight should align with your ability to comfortably handle it for extended periods.

- Specific Features: Look for additional features like variable speeds or integrated lights that can enhance your working experience.

Tool brands vary in quality and price. Balance cost with quality to find a tool that suits your budget and needs. Consider maintenance aspects, too. Remember to check for safety features, such as a secure grip or a blade guard on cutting tools. Safety should never be compromised for the sake of convenience or cost savings.

Maintenance Tips

Maintenance is of extraordinary significance to your power tools. Although it may seem inconspicuous, it is of great significance to maintaining the performance and extending the life of the power tool. Doing the following things will help your power tools reduce the chance of damage and keep them running longer.

Clean your tools regularly

Wipe down the exterior after each use to remove dirt, dust, and debris. Use an air compressor to blow out vents and hard-to-reach areas. Regular cleaning prevents grime from building up and affecting performance.

Lubricate moving parts as needed

Apply the manufacturer-recommended lubricant to gears, bearings, and other moving components to reduce friction and minimize heat buildup. Proper lubrication allows for smoother operation and longer tool life.

Store tools properly in a cool, dry place

Moisture and extreme temperatures can damage tools. Keep them in their original cases or a sealed cabinet/toolbox away from humidity, heat and direct sunlight.

Replace worn parts like blades, bits, brushes and belts

Dull or damaged components make the tool work harder, leading to overheating and premature wear. Use only manufacturer-approved replacement parts.

Follow the recommended maintenance schedule

Consult your owner’s manual for guidance on how often to service, sharpen, calibrate, and inspect your tools. Keeping up with regular maintenance prevents bigger problems.

Avoid overworking tools

Don’t push a tool beyond its limits or run it continuously without breaks. If it feels like it’s overheating or straining, let it cool down to prevent motor damage. Use the right tool for the job.