In the world of power tools, drones, electric vehicles, and countless industrial machines, the humble electric motor is the unsung hero. But not all motors are created equal. If you’ve ever wondered why your new cordless drill lasts longer and packs more punch than your old one, or why high-performance drones can maneuver with such precision, the answer lies in a fundamental choice: brushed vs. brushless motor technology.

This isn’t just an engineering debate; it’s a decision that impacts cost, performance, and longevity. In this guide, we’ll break down how they work, compare their pros and cons, and help you decide which one is the right choice for your application.

Brushed vs Brushless Motors: Quick Comparison

| Feature | Brushed Motors | Brushless Motors |

|---|---|---|

| Key Components | Brushes & a Commutator | Electronic Controller |

| How It Works | Brushes physically deliver power to spin the armature. | A controller electronically energizes stationary coils. |

| Cost | Lower | Higher |

| Efficiency | Lower (75-80%) | Higher (85-90%+) |

| Lifespan | Shorter | Longer |

| Maintenance | Required | Very Little |

| Speed & Power | Lower speed & power | Higher speed & power |

| Noise | Higher | Lower |

| Control Complexity | Simple | Complex |

| Best For | Budget projects, simple toys, low-duty uses | High performance, long life, efficiency |

What Are Brushed Motors?

Let’s start with the classic, the brushed motor. This is the type of motor that has been around for over a century, and its design is beautifully simple. If you’ve ever played with a toy RC car or used a basic power tool years ago, you’ve likely used a brushed motor.

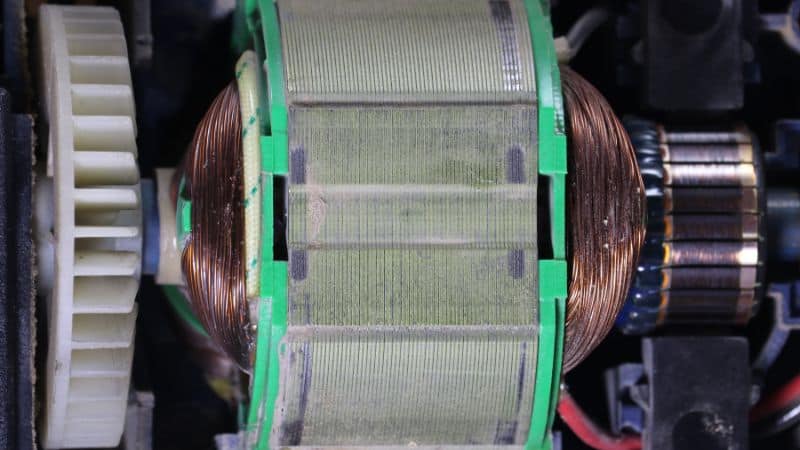

The key to its name lies in the “brushes.” These are small blocks of carbon that press against a part of the motor called the commutator. The commutator is a rotating switch on the motor’s shaft, made of copper segments.

Here’s how it works in simple steps:

- Power In: Electricity from the battery or power supply flows into the motor.

- The Brushes Deliver Power: The stationary carbon brushes carry this electrical power to the rotating commutator.

- Creating a Magnetic Field: The commutator sends the electricity into a set of copper wires wound around an iron core, called the armature (the part that spins). This creates an electromagnetic field.

- The Push and Pull: This electromagnetic field pushes and pulls against the permanent magnets housed in the motor’s outer casing.

- The Spin: This push-pull force causes the armature to spin. As it spins, the commutator rotates, and the brushes constantly make and break contact with different segments of the commutator. This constantly switches the direction of the electricity in the windings, keeping the motor spinning in one continuous direction.

In short, the brushes are the messengers that deliver the power and help change their direction to create motion. It’s a mechanical system that works very well, but because the brushes are always rubbing against the commutator, they slowly wear down over time.

What Are Brushless Motors?

As the name suggests, a brushless motor (often called a BLDC motor) does away with the brushes and the commutator. It’s a more modern design that has become incredibly popular. You’ll find them in everything from drones and high-end power tools to computer fans and electric vehicles.

So, how does it work without brushes? The entire system is flipped.

- The Flip: In a brushless motor, the permanent magnets are on the rotor (the part that spins). The copper wire windings, which now become the stator, are on the outside casing and do not move.

- Electronic Control: Since there are no brushes to act as a mechanical switch, an external electronic controller takes over. This small computer knows the exact position of the rotor using sensors (or sometimes by measuring the motor’s back voltage).

- Smart Power Delivery: The controller precisely energizes the outer windings in a specific sequence. By turning the coils on and off in the right order, they create a rotating magnetic field that “drags” the permanent magnet rotor around with it.

Think of it like a donkey chasing a carrot on a stick. The electronic controller is the person holding the stick, always moving the carrot (the magnetic field) just ahead of the donkey (the rotor) to keep it moving forward smoothly and efficiently.

Because there is no physical contact for switching the current, brushless motors are much more reliable and require far less maintenance.

Brushed vs Brushless Motors: Pros and Cons

Now that we know how they work, let’s compare them head-to-head.

Brushed DC Motor: Pros & Cons

Pros:

- Simple and Low Cost: The design is straightforward, making brushed motors very cheap to manufacture. This is their biggest advantage.

- Easy Control: Controlling their speed is very simple. You just vary the voltage going to the motor, which can be done with a basic, inexpensive circuit.

- No Complex Controller Needed: They can run directly from a DC battery without any extra electronics, which keeps the overall system simple and cheap.

- Reliable Torque at Low Speeds: They provide good starting torque and are effective at low speeds.

Cons:

- Lower Efficiency: A lot of energy is lost as heat due to friction from the brushes and electrical resistance. They are typically only 75-80% efficient, meaning a significant part of your battery power is wasted.

- High Maintenance: The brushes and commutator are wear-and-tear items. Eventually, the brushes wear out and need to be replaced, and the commutator can get dirty or damaged. This limits the motor’s lifespan.

- Lower Speed and Power: The physical limits of the brushes and the spinning armature mean they generally can’t spin as fast or be as powerful for their size as brushless motors.

- Electrical Noise: The constant sparking as the brushes make and break contact creates electrical noise, which can interfere with nearby electronics.

- Heat Management: Because the heat-generating windings are on the spinning rotor, it’s harder to cool the motor down effectively.

Brushless DC Motor: Pros & Cons

Pros:

- High Efficiency: With no energy lost to brush friction, BLDC motors are far more efficient, often reaching 85-90% or more. This means more power from your battery goes into actual work, leading to longer run times.

- Long Lifespan and Low Maintenance: There are no brushes to wear out. The only parts that wear are the bearings. This gives them a very long life and makes them almost maintenance-free.

- High Speed and Power Density: They can spin at much higher speeds and produce more power for their size and weight compared to brushed motors. This is why they dominate in drones and high-performance tools.

- Excellent Heat Management: Because the heat-generating windings are on the stationary outer shell, they can be cooled much more effectively, often allowing the motor to handle more power.

- Quiet and Clean Operation: The lack of sparking from brushes means less electrical noise and a smoother, quieter operation.

Cons:

- Higher Cost: The motor itself is more complex to build, and it requires an expensive electronic speed controller (ESC) to function. This makes the total system more costly.

- More Complex Control: You can’t just plug them into a battery. They need a smart controller to work, which adds complexity to the overall design.

- Potential for Controller Failure: While the motor itself is very reliable, the electronic controller is an additional component that can fail.

Which One Should You Choose?

Your choice between brushed and brushless ultimately comes down to your project’s needs, budget, and priorities. Here’s a simple guide to help you decide.

Choose a Brushed Motor if:

- Cost is Your Biggest Concern: You are building a project on a very tight budget, and the initial purchase price is the most important factor.

- Simplicity is Key: You want a motor that you can wire directly to a battery and a simple speed control knob without needing to program a complex controller.

- It’s for a Low-Duty Application: The motor won’t be used heavily or for long continuous periods. Think of a simple toy, a small fan, or a basic DIY project where long-term reliability isn’t critical.

- You Need Good Low-Speed Torque: For applications like a car’s power window motor, where you need strong, controlled movement at low speeds, a brushed motor can be a good fit.

Choose a Brushless Motor if:

- Performance and Efficiency are Top Priorities: You need maximum power, speed, and runtime from a battery. This is non-negotiable for drones, high-end power tools, and RC vehicles.

- You Need Long Life and Reliability: The application is critical, hard to reach for maintenance, or you just don’t want to worry about replacing parts. Examples include computer cooling fans, medical devices, or electric vehicle systems.

- Size and Weight Matter: You need a lot of power in a small, lightweight package.

- Your Budget Allows for It: You are willing to pay a higher upfront cost for better long-term performance, efficiency, and durability.

Frequently Asked Questions

Can you convert a brushed motor to a brushless one?

No, they are fundamentally different in their design and operation. You cannot simply modify one to become the other. You would need to replace the entire motor and add an electronic controller.

Are brushless motors AC or DC?

This is a common point of confusion. They are called Brushless DC motors because they are powered by a DC source, like a battery. However, the controller converts that DC power into a carefully timed 3-phase AC current that drives the motor. So, they run on AC, but the whole system is designed for a DC input.

Why are brushless tools more expensive?

The higher cost comes from two places: the more complex motor construction and the mandatory electronic speed controller. You are paying for advanced technology that delivers superior performance and efficiency.

Do brushless motors last forever?

While they have a much longer lifespan than brushed motors, they don’t last forever. Their bearings can eventually wear out, and the internal magnets can weaken over a very long time. However, under normal conditions, a brushless motor will almost always outlive the device it’s powering.

Is the speed control different for each motor?

Yes. Brushed motor speed is controlled by simply changing the voltage (e.g., with a potentiometer). Brushless motor speed is controlled by the electronic controller, which changes the frequency of the AC power it sends to the windings. This is a more complex but much more precise method.

Conclusion

The battle between brushed and brushless motors isn’t about one being universally better; it’s about choosing the right tool for the job.

As technology continues to advance and the cost of electronics drops, brushless motors are steadily taking over in more and more areas. But for now, the humble brushed motor still has its place, proving that sometimes, simple and affordable is exactly what you need.