How Much Power do My Tools Require?

When outfitting your workshop, understanding the specific power requirements of your power tools is crucial. This helps prevent overloading and ensures your setup has sufficient power for safety and efficiency.

Amp Needs Guidelines

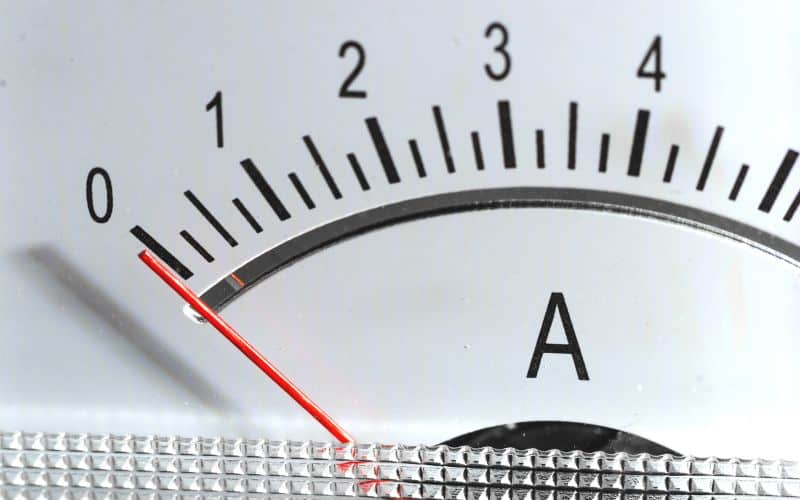

Power tools operate on a spectrum of amperage requirements based on their power capabilities and functionalities. The amp rating on the nameplate of a tool reveals how much current it will need under a full load.

- Small power tools such as sanders and jigsaws typically require 2 to 8 amps.

- Larger power tools, which include circular saws, table saws, and lathes, often need 6 to 16 amps.

- Hefty machinery like dust collectors and air compressors may demand 20 amps or more.

Corded tools will draw power directly from your electricity supply, so you’ll need to ensure the wattage, calculated by multiplying voltage by amps, can be supported by your workshop’s electrical system. On the other hand, cordless tools rely on batteries, where the principal consideration is the battery voltage and amp-hours, which will dictate the power available and the duration of operation.

Remember to consider tools that can be wired to run on 240 volts instead of the standard 120 for more efficient power use and to potentially reduce the amperage needed. For example, some larger power tools could be more energy-efficient at a higher voltage.

Key factors like duration of use, the simultaneity of multiple tools operating, and power consumption peaks must be part of your planning. Equip your workshop not just for the present but also for future tools with possibly higher requirements.

It’s imperative to refer to your tool’s user manual or the information provided on its nameplate to ascertain the exact amp needs. If in doubt, consulting an electrician can provide clarity on electricity supply and wattage requirements tailored for your workshop configuration.

How do I Size My Subpanel and Circuits?

If you’re considering the sizing of your subpanel, it’s important to evaluate the capacity needed for the electrical demands of your power tools. Here’s how you can determine the appropriate size for your subpanel and circuits:

- Calculate Total Amperage: Begin by listing the amperage needs of each tool, usually found on the nameplate. Sum up these values to estimate the total amperage your shop wiring will require.

- Follow Electrical Codes: According to electrical codes, the subpanel you select should not exceed 80% of its maximum load capacity. This means that if your cumulative electrical current requirement is 40 amps, you opt for a subpanel with at least a 50-amp rating for safety.

- Choose the Circuit Breaker: Your circuit breaker acts as a safety mechanism and should be sized to handle the load. If your total load comes to 48 amps, rounding up to the next standard size would mean using a 50-amp circuit breaker.

- Selecting Wiring: Ensure that you use the correct gauge of wiring to support the electrical current. For a 60-amp subpanel, for instance, a 6 gauge wire is generally suitable unless the distance requires a heavier gauge such as a 4 gauge.

Before starting, it’s strongly advisable to consult with a licensed electrician. They are trained to understand the nuances of electrical circuits and can ensure that your setup meets all local regulations and electrical codes. Incorrect sizing can lead to unsafe conditions or inefficient power output. Remember, your safety and the reliability of your power tools rely on proper circuit and panel sizing.

Do I Have Adequate Power to Draw from?

Determining if your household electrical system can handle your power tools involves assessing the capacity of your electrical panel and the amp needs of your tools. Most homes built in the last four decades generally have enough capacity to run common power tools. However, safety and efficiency are critical, so it’s essential to consider the load you’ll be placing on the system.

Firstly, check the nameplate on your power tool, which will list its amperage draw. Small power tools, like sanders or jigsaws, typically require between 2 to 8 amps, while larger tools, such as routers or table saws, may draw 6 to 16 amps.

Now, look at your electrical panel. The capacity of a standard household panel can range from 100 to 200 amps. It’s vital to ensure that the total amperage of all running equipment and appliances does not exceed 80% of the panel’s capacity — this is for safety and to prevent potential overloading.

For example:

- If your panel is rated at 100 amps, the safe maximum load shouldn’t be more than 80 amps.

- Running a router (6 amps) and a sander (4 amps) simultaneously requires 10 amps of current.

Ensure that your panel can handle the cumulative draw of your tools. If the load from your equipment, combined with other household demands, stays below this 80% threshold, your system is likely adequate. However, if the cumulative load approaches the capacity, it may impact the efficiency of your tools and could lead to an increase in your electricity bills due to the added stress on the system.

To avoid any risk, consider consulting with an electrician to evaluate your specific electrical needs and panel capacity.

How Can I Save Power While Using Power Tools?

In terms of using power tools, there are effective ways to enhance efficiency and safety while managing power consumption. Your understanding of these strategies will not only extend the lifespan of your tools but also conserve electricity and reduce your bills.

- Select Cordless Tools Carefully: Opt for power tools with lithium-ion batteries for better longevity and power efficiency. When these aren’t in use, remove the battery from the tool and store it in a cool, dry place to prevent power drain.

- Maintain Your Tools: Keep your power tools clean and well-maintained. A clean and lubricated tool reduces friction, thus enhancing performance and reducing electricity usage.

- Use the Right Tool for the Job: Employing a tool that’s too small for a heavy-duty project can lead to inefficient power use and strained equipment. Conversely, larger tools consume more power and may be overkill for smaller tasks.

- Operate at Optimal Speeds: Utilizing the correct speed and pressure can improve the efficiency of your power tools. Excessive speed wastes electricity without improving performance.

- Keep Batteries and Chargers in Check: Use a smart power tool battery charger that prevents overcharging, which can consume unnecessary power and lessen battery life. Plus, ensure your charger is unplugged when not in use to avoid phantom power consumption.

- Plan Your Work: Reduce idle run time by planning your tasks. Turn off tools between uses instead of leaving them running.

Remember that wattage specifies the power consumed by the tool; addressing the factors that affect wattage will help you save electricity. By combining these practices, you’ll be able to efficiently manage your power tool use with confidence, knowing you’re optimizing for performance and energy economy.

Is Rewiring to 240 Volts the Best Practice?

When considering the efficiency and performance of your power tools, you may contemplate if operating on 240 volts is advantageous. Rewiring to a higher voltage, such as 240 volts, generally enhances the performance of power tools—especially those with higher wattage requirements. This is because power tools draw less current at 240 volts than at 120 volts, allowing for a more efficient operation.

- Efficiency: At 240 volts, the electricity consumed by power tools is more efficiently used. For instance, when you convert tools like a table saw or dust collector to 240 volts, the total amperage used by these tools can decrease significantly, resulting in less strain on your electrical system.

- Safety: Adhering to proper electrical codes is essential. If rewiring is on your agenda, it’s critical to consult or hire a certified electrician to ensure the work meets safety standards. Upgrading wiring may also be necessary when transitioning to 240 volts to handle the increased voltage safely.

- Electrical System Impact: Your overall electrical system may benefit from the switchover, as higher voltage circuits can lead to a balanced load on the system. Appliances and tools running on 240 volts can often operate on fewer circuits, further streamlining electrical consumption.

Keep in mind that not all power tools are designed for 240 volts, and conversion is not universally beneficial or necessary. It is imperative to check the specifications of your tools and the capabilities of your electrical system before deciding to rewire. Always prioritize compliance with electrical codes to maintain a safe working environment.

FAQ

How many amps do power tools typically use?

Power tools have a wide range of current (amp) ratings depending on the size and type of tool. Here is a summary of typical amperage ranges for various power tools:

- Small portable power tools (sander, jigsaw, etc.): 2 to 8 amps

- Larger power tools (router, circular saw, table saw, lathe, etc.): 6 to 16 amps

- Surge impact driver: 2.6 amps, no load, up to 20.5 amps max

- Compact impact wrench: 17-20.5 amps max

- Oscillating multi-tools: 2.6-6.5 amps typical, 21-32 amps max

- Backpack vacuum: 8.8-15.9 amps

- Compact blower: 5-17 amps

- Other tested tools ranged from 11-55 amps max draw

- 18V cordless drills: around 30 amps max when stalled, much lower during normal use

- Corded power tools: often rated for 8 amps at 120V which is around 1000 watts. Cordless versions are typically around half the power of corded, so 500 watts or around 30 amps at 18V

In general, larger tools like table saws and routers will draw more current than smaller tools. Cordless tools powered by 18V lithium-ion batteries can have very high peak current draws of 30-50+ amps but much lower average draw during use. The amperage rating on corded tools indicates the maximum sustained current the tool can handle without overheating, not necessarily the actual current drawn during use.

What are the power requirements for air compressors?

Air compressors have diverse power needs. Small home compressors generally use about 10-15 amps, whereas industrial models could demand 20 amps or more. Remember to multiply the voltage by amperage to determine the wattage.

Is there a safety hazard with higher amperage tools?

Indeed, tools with higher amp ratings can pose a safety hazard if not used correctly. Ensure that your circuit breaker is rated appropriately to prevent overheating and potential electric charge issues. Always wear protective gear and adhere to proper maintenance procedures to enhance durability and safety.

What does “amp rating” mean?

An amp rating describes the maximum amount of electrical current that a tool can draw safely. Tools with a higher rating are typically designed for more demanding tasks such as drilling and sanding, and they often offer enhanced features, though this might impact their maintenance needs.

Remember, using power tools within their recommended limits ensures safety and efficiency, avoiding undue stress on both the tool and the power source.