Types of Portable Power Tools

When you’re tackling projects, be they DIY or professional, having the right portable power tools can significantly enhance your efficiency and the quality of your work. Here’s a selection of common portable power tools that you might find indispensable:

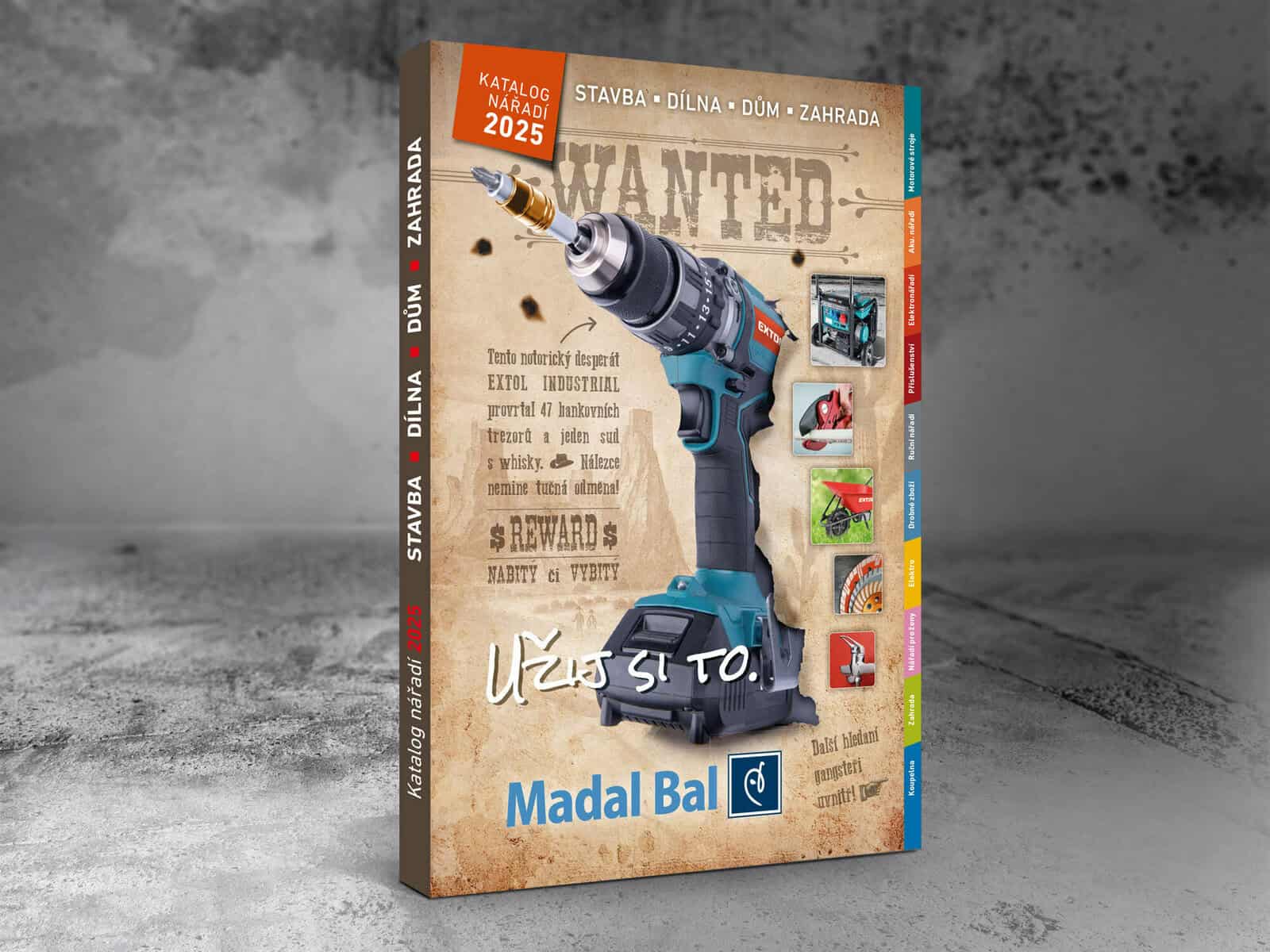

- Drills: Among the most versatile power tools, with options ranging from cordless drills to hammer drills, they allow you to make holes and drive screws with ease.

- Circular Saws: Essential for cutting straight lines across a variety of materials; they are powerful and offer precision, making them a staple for carpentry.

- Sanders: To smooth surfaces efficiently, electric sanders are invaluable. They can be used on wood, metal, or plastic.

- Jigsaws: Renowned for their ability to cut curved and complex shapes in wood and metal, jigsaws are a must-have for intricate work.

- Impact Drivers: These tools are specifically designed to handle tough screwdriving jobs with more torque and less effort than a standard drill.

- Grinders: Ideal for cutting, grinding, and polishing, grinders are useful in metal fabrication and construction work.

- Miter Saws: Perfect for making precise crosscuts and miter cuts, these saws are vital for anyone working in framing or molding.

- Chainsaws: When you need to cut down trees or large branches, a portable chainsaw is your tool of choice.

- Nail Guns: They make quick work of driving nails into wood or other materials, proving to be more efficient than a hammer.

In addition, an oscillating tool is a versatile option that can perform a range of tasks from cutting and sanding to scraping and polishing, thanks to its interchangeable blades and attachments.

Each of these tools is designed to make your work easier and more efficient. Select based on your specific project needs and ensure you have the right tool for the job.

Power Source and Mobility

When you select a portable power tool, the power source significantly affects mobility and practicality. Understanding the differences between corded and cordless power tools, as well as advancements in battery technology, helps you make an informed choice that aligns with your needs.

Battery Technology

Battery Pack Advances:

- Modern lithium-ion batteries are lighter and provide longer run time

- Capacity is measured in ampere-hours (Ah); higher numbers indicate longer operation

- Advancements have led to faster charging and longer-lasting battery packs

By considering these aspects, you can better determine which type of portable power tool suits your work, whether it requires the mobility and convenience of a cordless tool or the sustained power of a corded one.

Tool Selection and Usage

Choosing the Right Tool for the Job

To ensure precision and efficiency in your projects, whether it’s woodworking or general construction, you must choose the power tool that best fits the task at hand. For straight cuts in wood, a circular saw is invaluable, while for fine sanding to achieve a smooth finish, an orbital sander is more suitable.

- Circular saw: Ideal for making straight cuts and plunge cuts.

- Drill: Used for drilling holes with precision. But remember, not all drills are the same; some may be more powerful or offer additional features such as hammer action.

Selecting a tool also involves considering the material you’ll be working with and the type of cut required, such as bevel cuts or miter cuts. Your power tool should not only match the job but should also be comfortable for you to handle and operate.

Operating Instructions and Techniques

Before using any power tool, familiarize yourself with its operating instructions to maximize both safety and functionality. Here are some specific techniques for common tools:

- Drill:

- Use sharp drill bits for clean, precise cuts.

- Apply steady pressure and start at a low speed to avoid slipping.

- Circular saw:

- Support the material being cut securely.

- Keep the saw’s base plate flat against the material to ensure straight cuts.

Always follow the manufacturer’s guidelines and use protective gear. Proper usage impacts not just the outcome of your project but also ensures the longevity of your power tools.

Safety and Maintenance

In terms of dealing with power tools, your safety and the longevity of your equipment depend largely on proper handling and diligent maintenance. These practices are critical because the misuse of power tools can lead to dangerous situations, while consistent maintenance ensures tools remain in optimal working condition.

Safe Handling of Tools

Using power tools safely requires adherence to stringent guidelines to minimize risks. Before operating any power tool, always:

- Conduct an Inspection: Examine the tool for damage, ensuring all guards and safety devices are in place and functional.

- Wear Appropriate PPE: Use personal protective equipment like goggles, gloves, and ear protection.

- Attend to Your Surroundings: Keep your workspace clean and well-lit; clutter and poor lighting can lead to accidents.

Remember that tools like nail guns or equipment utilizing compressed air demand extra caution due to the potential for flying debris or sudden ejections.

Proper Maintenance Practices

Maintenance is the bedrock of power tool care. To keep your tools running efficiently and extend their lifespan, consider the following:

- Regular Cleaning: Wipe down tools after use, removing any dust or debris. Be particularly careful with tools such as sanders or drills that can accumulate fine particles.

- Scheduled Servicing: Follow the manufacturer’s recommended maintenance schedule for tasks like lubrication, filter changes, and battery care.

- Storage: Store your power tools in a dry, safe place to prevent rust and damage from temperature extremes or damp conditions.

By focusing on the safe handling of your power tools and committing to proper maintenance practices, you can ensure these valuable investments are both reliable and durable.

Material Applications

In your DIY projects or professional work, you handle various materials, each requiring specific tools for optimal results.

Wood: Essential for carpentry, you use portable power tools like drills and circular saws to cut, shape, and join wooden pieces. When working with lumber, precise measurements are crucial for successful framing and molding applications.

Plastic: Lightweight and versatile, plastic demands finesse. Tools such as jigsaws allow you to cut intricate shapes, while orbital sanders ensure a smooth finish without melting the material.

Metal: Robust and durable, metalworking requires powerful tools with certain characteristics. Impact drills and angle grinders cut through tough metal surfaces and are especially useful for crafting and assembling metallic frames.

Tile: Laying tile involves accurate cutting to ensure it fits perfectly. A wet tile saw is your go-to tool, as it cleanly slices through ceramic or stone without cracking the surface.

When choosing your portable power tools, consider the specific needs of these materials to achieve the best outcome. Your choice impacts the efficiency and quality of your work, whether it’s intricate detailing in wood, precise cuts in plastic, robust alterations in metal, or delicate handling of tile.

Tool Specifications and Features

Understanding Power and Performance

The power and performance of portable power tools are measured by two key parameters: torque and speed. Torque refers to the turning force of the tool—measured in Newton meters (Nm)—and affects its ability to drive screws or fasten hardware. Speed, indicated in rotations per minute (RPM), relates to how fast the bit or blade moves, influencing cutting, drilling, or driving efficiency. Many tools offer variable speed controls, allowing you to adjust the RPM to suit different materials and applications.

Ergonomics and Design

Ergonomics and design play pivotal roles in the long-term usability of power tools. A lightweight tool reduces user fatigue, enabling you to work longer without discomfort. Ergonomic features like cushioned grips and balanced weight distribution contribute to the tool’s ease of use and can diminish strain on your body. Tools designed with your natural handling postures in mind enhance overall control and diminish the risk of repetitive motion injuries.

- Lightweight: Essential for prolonged use without causing user fatigue.

- Ergonomics: Includes features like padded grips and helps prevent strain.

By paying attention to these specifications and design features, you will be able to choose portable power tools that are not only powerful and capable for your needs but also comfortable to use for extended periods.

Accessory and Attachment Options

The right accessories and attachments can transform your portable power tools into multi-functional devices, allowing you to perform a wide range of tasks with precision and efficiency.

Enhancing Tools with Accessories

Accessories such as drill bits and saw blades are indispensable for many power tools. Drill bits come in various sizes and materials, tailored for different surfaces, from softwood to hardened steel. Picking the correct drill bit ensures clean, precise holes for screws, nuts, and bolts. Sanding discs attach to power sanders and come in a variety of grits; finer grits yield a smoother finish, while coarser grits are ideal for removing material quickly.

Attachments for Specialized Tasks

For tasks requiring specific functionality, there are attachments that can be added to your tools. Attachments like angle grinders or biscuit joiners can be used with drills to perform tasks beyond just drilling holes or driving screws. With these specialized attachments, you can expand the capabilities of your tools far beyond their original purposes.

Comparisons and Selection Guides

Corded vs. Cordless Tool Comparison

| Feature | Corded Tools | Cordless Tools |

|---|---|---|

| Power Source | Electrical outlet | Batteries |

| Run Time | Unlimited | Limited by battery life |

| Mobility | Restricted by cord | High |

| Power Output | Consistent | Dependent on battery |

| Initial Cost | Lower | Higher – |

When considering a brand, look for those with reputable performance in both corded and cordless arenas. Brands may offer unique ecosystems where batteries are interchangeable among tools within the same voltage family or series. Use a selector guide provided by brands to match your specific needs with their tool offerings.

Remember, your choice between corded and cordless should be guided by the specific requirements of your projects. Always consider the tool’s power needs, job site conditions, and frequency of use before making your decision.

Frequently Asked Questions

How do you classify different types of portable power tools?

Portable power tools are typically classified by their power source: electric, battery-powered, pneumatic, or hydraulic. Each type is suited for different environments and tasks, from DIY projects to professional construction work.

What are some examples of the most commonly used portable power tools?

Commonly used portable power tools include drills, circular saws, sanders, and impact drivers. These tools are valued for their versatility and convenience in handling a variety of tasks.

What are the main differences between handheld power tools and stationary power equipment?

Handheld power tools, which are often battery-operated, offer mobility and ease of use in diverse locations. In contrast, stationary power equipment is designed for stability and typically offers more power and efficiency for repetitive or heavy-duty tasks.

In what situations are portable power tools preferred over stationary equipment?

Portable power tools are preferred when your work requires movement, such as on construction sites, or when the job is at a remote location without access to electrical outlets. Their portability also makes them ideal for tasks that demand versatility and the ability to quickly switch between different tools.

What maintenance procedures should be followed for portable power tools to ensure their longevity and safe operation?

To ensure longevity and safety, regularly clean your tools, check for wear and tear, and store them in a dry, secure place. Follow the manufacturer’s guidelines for maintenance, including lubricating moving parts and routinely checking battery health for cordless tools.