Brushless refers to a type of motor used in power tools. It is also called a brushless DC motor. Compared to the traditional brushed motor, you may know little about brushless power tools.

This article covers the concepts and applications of brushless motors, as well as comparisons with brushed motors, to help you have a deeper understanding of these two types of power tools and help you make a wise purchasing decision.

Brushless Technology Explained

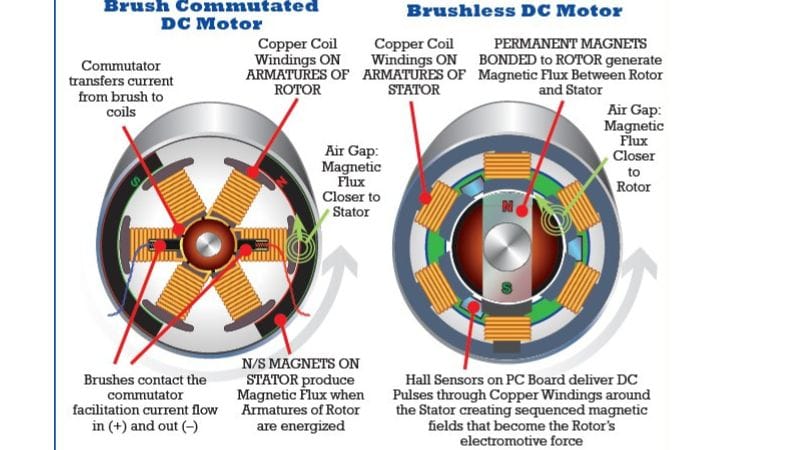

Brushless motors, as their name implies, operate without the brushes and commutators found in traditional motors. These brushes are part of a system that delivers power to the motor’s spinning part, or armature. In a brushless motor, an electronic controller replaces the function of the brushes, providing energy to the motor windings.

In this design, the permanent magnets are attached to the rotor (the spinning part), and the electromagnets are stationary within the stator. The electronic controller rapidly switches the magnetic field in the stator to attract and repel the permanent magnets on the rotor, causing it to turn.

The elimination of brushes means there’s no physical contact that would cause friction and wear. This results in a motor that’s more responsive and can adjust its speed and power to match the task without the limitations of a brush-commutator system.

Brushless vs Brushed Motors

So, what are the differences between brushed and brushless motors? Here is a summary.

| Feature | Brushless Motors | Brushed Motors |

|---|---|---|

| Commutation | Electronic controller | Mechanical commutator and brushes |

| Friction and Heat Generation | Lower due to lack of brushes | Higher, leading to wear and inefficiency |

| Maintenance | Minimal, no brushes to replace | Brushes need regular replacement |

| Response to workload | Automatic adjustment | Manual adjustment required |

| Efficiency and Battery Life | Higher efficiency & longer run times | Less efficient & shorter battery life |

Pros and Cons of Brushless Motors

As a new technology, a brushless motor has both advantages and disadvantages.

Pros of Brushless Motors

Using a brushless motor has several advantages:

- No physical brushes and commutators: Brushless motors do not have the carbon brushes or commutators found in brushed motors. Instead, they use a small circuit board to coordinate energy delivery to the windings that surround the magnets on the armature. This contactless, friction-free design allows for more power, torque, and speed without overheating.

- Less maintenance needed: Without the friction-producing brushes that wear down over time, brushless tools last up to 50% longer than brushed tools. They require less maintenance since there are no brushes to replace every few years.

- More compact and lightweight: The absence of brushes and commutators allows brushless tools to be made smaller and lighter. This makes them easier to use for long periods and to get into tighter spaces.

- Higher efficiency: Brushless motors often run on battery power up to 50% longer than brushed motors. The electronic control can adjust power based on the task, optimizing battery usage and reducing energy loss.

- Quieter operation: The lack of physical contact inside the motor makes brushless tools run more quietly and with less vibration compared to brushed versions.

Cons of Brushless Motors

A brushless motor is not perfect. Here are the flaws:

- Higher cost: Brushless motors are typically more expensive than brushed motors due to the complex electronic controls required for operation. The added electronics and control circuitry increase the manufacturing cost

- Complex maintenance: Brushless motors require specialized knowledge and equipment for repair and maintenance, making them less accessible to the average user. The added complexity also means a higher chance of failure compared to simpler brushed designs.

- Higher power requirements for controller: The electronic controller for a brushless motor consumes additional power, slightly reducing the overall efficiency advantage over brushed motors.

- Sensitivity to extreme conditions: Some users have reported that brushless tools can be more sensitive to extreme temperatures, humidity, and other environmental factors compared to brushed tools.

- Discrete speed control: Brushless tools with variable speed triggers can have noticeable discrete speed steps, while brushed tools often have smoother, truly variable speed control.

Brushless and brushed motors both have distinctive features. Your purchase decision needs to consider many aspects: budget, use, and other aspects you are concerned about.

Application of Brushless Power Tools

Due to the appearance of brushless technology, the brushless motor is widely used in many tools, like brushless drills, brushless saws, and so on.

- Drills and Drivers: Brushless drill/driver combo kits are very popular for general DIY and construction use.

- Impact Drivers and Wrenches: Brushless impact drivers provide high torque in a compact size for driving fasteners. Impact wrenches have even more torque for tasks like removing lug nuts.

- Saws: Brushless circular saws, reciprocating saws, jig saws, and cut-off tools are available for cutting wood and metal.

- Grinders and Sanders: Brushless angle grinders and sanders allow for powerful grinding, sanding, and polishing without being tethered to a cord.

- Routers and Planers: Compact brushless routers and planers make it easy to do trim work and smooth surfaces.

- Nailers: Brushless cordless nail guns speed up nailing compared to using a hammer and allow easy movement around job sites.

- Outdoor Power Equipment: Brushless motors are being used in string trimmers, blowers, chainsaws and other battery-powered outdoor tools for improved performance.

Innovations in Brushless Power Tools

The advent of brushless motor technology in power tools has led to numerous innovations:

- Cordless Power Tool Advancements: The reduction in size and weight of brushless motors has led to smaller and lighter cordless tools that are easier to handle, especially in tighter spaces.

- Improved Tool Performance: Power tools with brushless technology deliver power more efficiently, meaning you get tools that are not only more powerful but also last longer compared to brushed motor tools.

Maintainance Tips

Maintaining your brushless power tools is crucial for ensuring longevity and optimal performance.

This section will guide you on how to preserve the life of your tools and follow operational best practices.

Preserving Tool Life

Your brushless tools are designed to be easier to maintain than their brushed counterparts. With no carbon brushes to replace, you’ll face fewer maintenance tasks. However, there are some steps you should take:

- Cleaning: After each use, wipe down the tool to remove any dirt and debris.

- Use compressed air to blow out any particles from the motor housing and moving parts.

- Battery Care: For battery-powered tools, it’s important to keep the power supply in good condition.

- Store batteries at room temperature and recharge them before they are completely drained.

- Storage: Proper storage is key to tool preservation.

- Keep your tools in a clean, dry place to protect them from moisture and extreme temperatures.

Operational Best Practices

Operational efficiency isn’t just about how you work; it’s about how you treat your tools.

Consider these tips:

- Regular checks for wear and resistance in moving parts can save you from bigger issues down the line.

- Ensure the power supply is stable and matched to the tool’s requirements to maintain energy efficiency.

- Operating the tool within its intended capacity minimizes noise, eliminates unnecessary sparks, and reduces overall wear, helping to extend the life of your brushless tool.

By following these steps, you can keep your brushless tools in top condition, ensuring that they’re ready for the job at hand whenever you need them.