Industrial Welding Inverter, 200 A, Smart

Model:

8796012

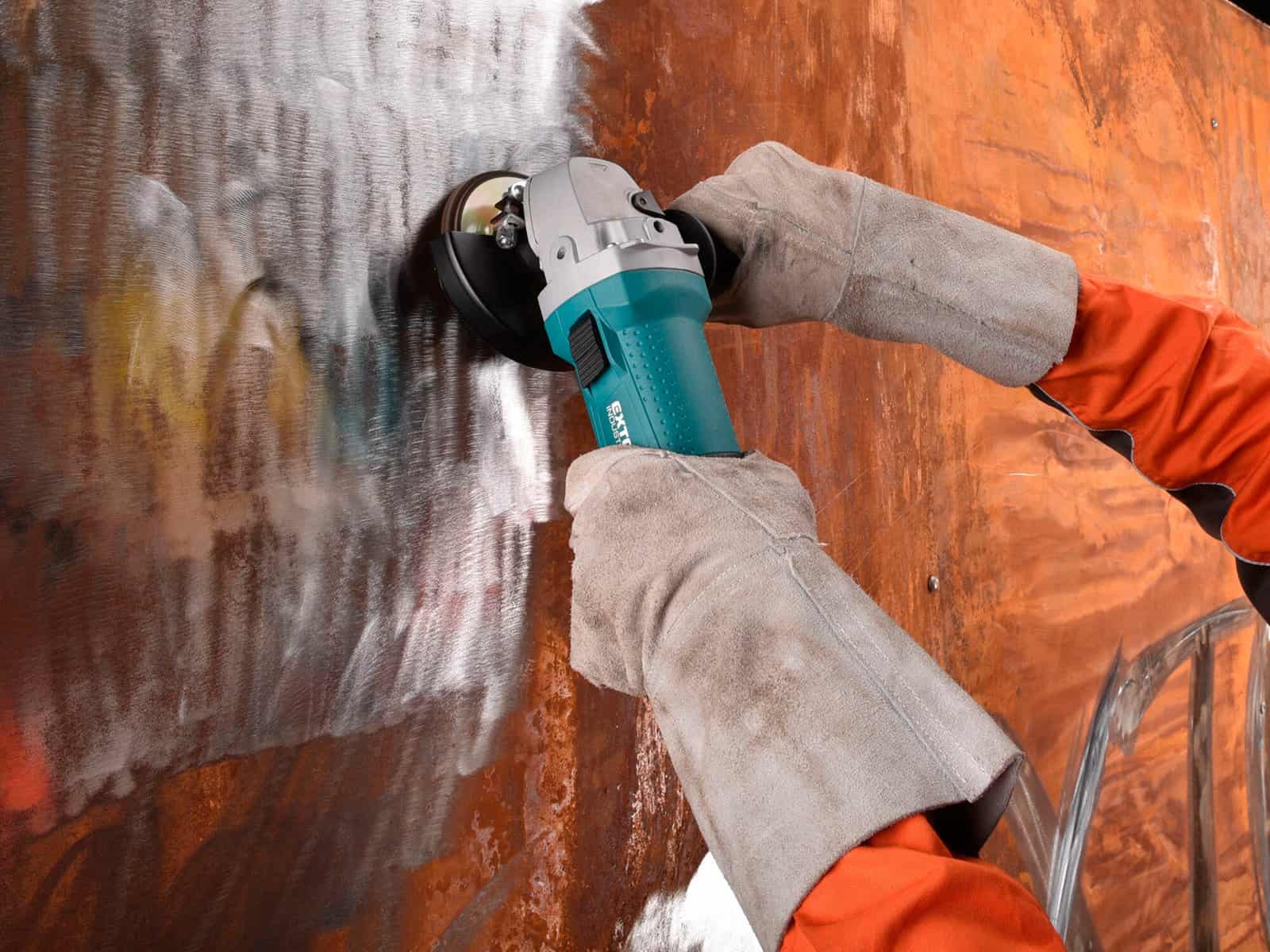

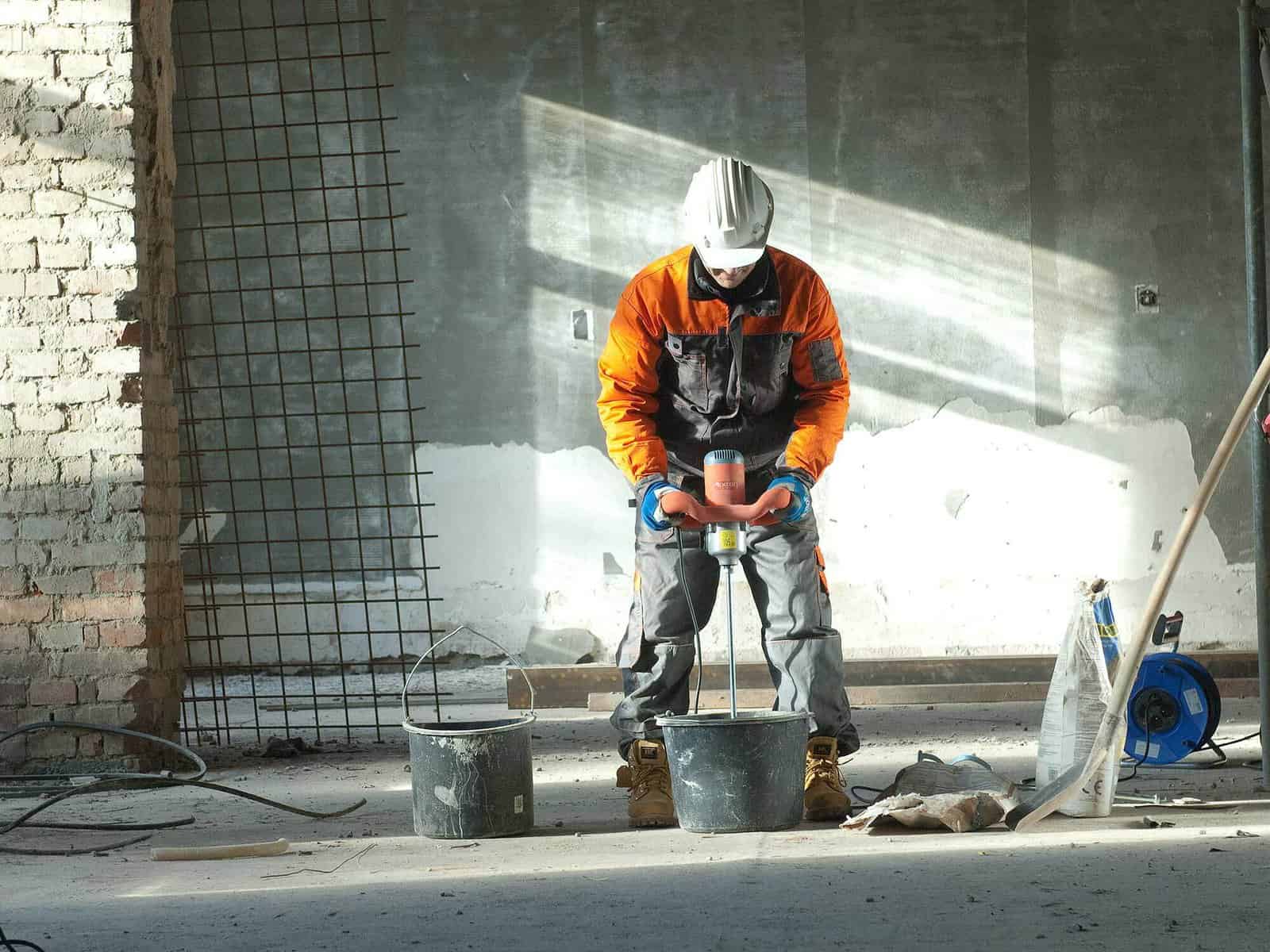

Category: welding inverters

The industrial welding inverter 200 A Smart is a powerful and versatile welding machine with advanced technologies, high-duty cycle, and automatic protection for safety.

| voltage/frequency | 220-240V/50Hz |

|---|---|

| welding current | 10-200A |

| no-load voltage | 63V-MMA, 63V-TIG |

| max. effective power supply | 26A-MMA, 17A-TIG |

| protection at maximum current | 32A-MMA, 25A-TIG |

| duty cycle MMA | pri 40°C – 200A/30%, 145A/60%, 110A/100% |

| electrodes diameter | 1,6-5,0mm |

| type of electrodes | MMA (rutile, basic, INOX…), TIG (tungsten) with additional equipment |

| technology | Hot Start, Arc Force, Anti-Stick, Lift TIG |

| connector | quick coupler 35-50 |

| weight | 4,5kg |

| packaging info | weight: 5.4 kg |

You may also like…

-

8798271

- The industrial welding inverter 200 A Smart is a powerful and versatile welding machine that is perfect for industrial use.

- With a voltage/frequency of 220-240V/50Hz and a welding current range of 10-200A, this inverter can handle a wide variety of welding tasks.

- It also features advanced technologies such as Hot Start, Arc Force, Anti-Stick, and Lift TIG, making it easy to use and ensuring a high-quality weld every time.

- The high-duty cycle and consistent output welding current allow long-term continuous operation even in high temperatures.

- This welding inverter also has automatic protection against undervoltage, overvoltage, and overheating, ensuring safety during use.

- With its compact size, low weight, and quick coupler connectors, this welding inverter is portable and convenient for use in any location.

Request A Quote

Contact Form

"*" indicates required fields

Related articles

Related products

Related products

-

8896025

-

8896024

-

8796011